Factory Price Impresión de pantalla plástica de la botella - Four-Post Semi-automatic Screen Printing Machine – Lanlin Printech Detail:

Four-Post Semi-automatic Screen Printing Machine

Advantages:

• Mitsubishi PLC control, HMI touch screen control panel, easy operation;

•Equipped with TWO Panasonic servo motors, one driving print carriage, the other peel-off ;

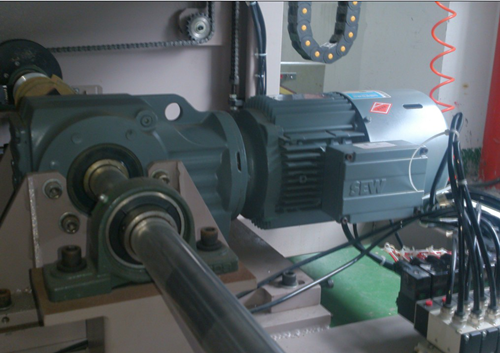

•Equipped with TWO SEW motors to control the frame up/down and print table in/out movement;

•Print head and table motion on German Rexroth linear guide rail+ high quality timing belt, smooth and precision;

• Reciprocating vacuum bed allows easy loading and take-off of substrate while keeping registration;

• Aircraft-quality, 50mm thick, cast iron table provides the heaviest gauge plate in the industry;

• Four-post, horizontal head lift accommodates substrates of up to 1″ thick;

Standard Feature:

• Front or Rear Carriage Stop Mode: A toggle switch on the main control panel stops the carriage in flood (solvent system) or non-flood (UV curable) mode

• Master-frame: Accepts all frame types, including roller frames

• Peel Rate Setting: Adjustable without tools; allows easy access and fine adjustments to the automatic peel system

• Position Settings for Front and Rear Screen Holders: Requires no tools to set and can be positioned to accommodate smaller screens

• Aircraft-quality cast iron table:

2″ thick table with the heaviest gauge plate in the industry

• Double Print Feature: Allows extra-heavy ink deposits when required

• Variable Speed Take-Off: Adjusts speed to match conventional or UV dryer conveyors

• Reciprocating Vacuum Bed: Allows for easy loading and take-off of substrate, while maintaining perfect registration

• “0” Off-Contact: Easily accessible controls allow minimal off-contact settings to take advantage of high-performance, high-tension screens (at maximum frame size)

• Three-Way Mode Selection: Allows operator to choose timer, jog or foot pedal mode

Independent Squeegee & Flood-bar Speeds: Helps ensure excellent print quality control

• Squeegee/Flood-bar Angle Adjustments: For absolute print control on challenging jobs

• Independent Carriage Stroke & Head Lift Drive: Provides smooth, even print stroke

• Four-Post Head Lift: Allows printing on material up to 1″ thick

• Sliding Pneumatic & Manual Screen Clamps: Provide fast setup and changeover of different screen sizes

• Extra “Head Room”: Head rises up to 18″ for easy screen cleaning with safety interlocks

• Horizontal Lift System: Ensures even flooding for even ink deposits

• Squeegee/Flood-bar Pressure Adjustment: Provides tool-free, easy access to micro-calibrated knobs

• Super Micro-Registration: New bearing- actuated system provides precise registration with tolerances to +/-.002″

• Squeegee Skew System: Improves ink distribution and uniformity through mesh

Specifications:

| Model |

LL-CP70100SP-1 |

LL-CP95155SP-1 |

LL-CP1323SP-1 |

| Max. Print size (mm) |

700X1000mm |

950X1550mm |

1300X2300mm |

| Print table size(mm) |

950X1250mm |

1200X1750mm |

1550X2550mm |

| Max frame size (mm) |

1200X1400mm |

1450X1950mm |

1800X2700mm |

| Table Precision (mm) |

±0.05mm |

±0.05mm |

±0.05mm |

| Printing Precision (mm) |

±0.03mm |

±0.03mm |

±0.03mm |

| Print thickness(mm) |

≤30mm |

≤30mm |

≤30mm |

| Max Print speed(P/H) |

500 pcs/Hour |

400 pcs/Hour |

350 pcs/Hour |

| Air pressure (kgf/c㎡) |

4-6 |

4-6 |

4-6 |

| Power Supply(V/KW) |

380V 50/60Hz, 4.2KW |

380V 50/60Hz, 4.2KW |

380V 50/60Hz, 4.2KW |

| Machine weight (kg) |

1400 kgs |

1700 kgs |

2500 kgs |

| Machine size(L*B*H)(mm) |

1900*2735*1500 |

2150*3285*1500 |

2500*4035*1500 |

Product detail pictures:

Related Product Guide:

Dye Sublimation Printing Vs Screen Printing – What’s the Difference?

Screen Printing T-Shirts: Design Your Own T-Shirt for Screen Printing

Factory Price Impresión de pantalla plástica de la botella - Four-Post Semi-automatic Screen Printing Machine – Lanlin Printech, The product will supply to all over the world, such as: , , ,