Application:

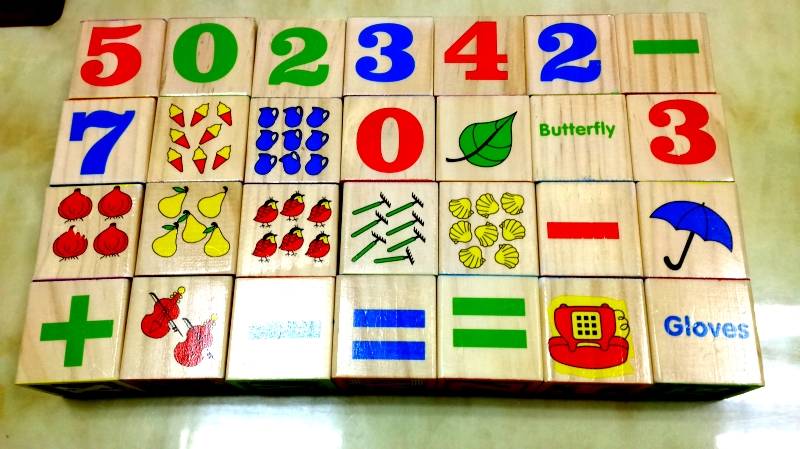

Applicable to flat and round part heat transfer printing for plastic, hardware, electronic product, toy, stationery and wood.

Feature:

1. Equipped with PLC programmable controller text in computer, can be displayed on operation screen. With digital setting, it has high sensitivity. With key-type panel, it is simple and convenient;

2. With straight elbow lifting air cylinder, it has fast speed; Controlled by photoelectronic sensor, the machine has high accuracy;

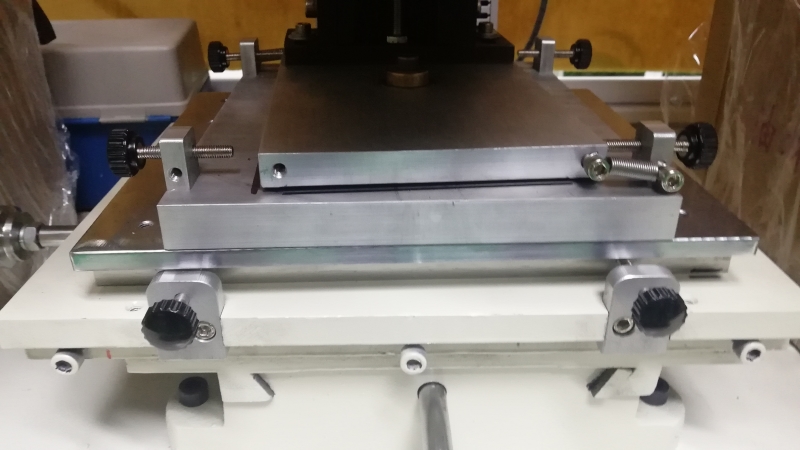

3. With air cylinder shutting left and right through horizontal push, it is steady and has big pushing force. Workbench can be adjusted back/front and left/right, which is convenient for fast operation;

4. Pressure, temperature and time for transfer printing are adjustable;

5. Positioning transfer printing film with electric eye can load and wind paper automatically and is adjustable;

6. With tension motor imported from Taiwan and magnetic powder brake, it is accurate and steady;

7. The most advanced special transfer printing jig, good and steady transfer printing result;

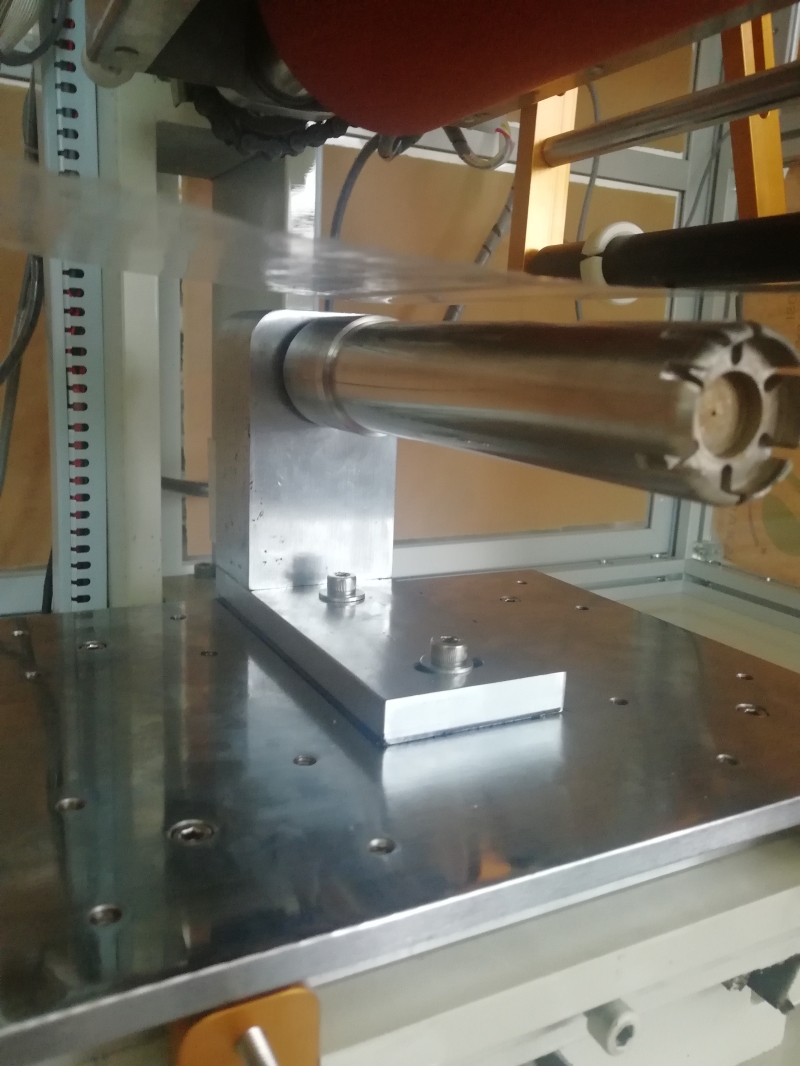

8. Height of hot stamping head is adjustable; Heating tube is featured by wrap-around heat conduction, so that hot stamping heat keeps uniform temperature;

9. Lifting guide post of machine is enlarged to increase pressure and keep uniform pressure. 5 Film guide arms get thick, so as to realize excellent balance;

Specification:

| Stamping diameter for round part: | 150mm |

| Printing area for flat part: | 250*400mm |

| Stroke of cylinder: | 400mm |

| Maximum height of part: | 200mm |

| Stamping speed: | 1000 pieces per hour |

| Stamping temperature range: | 320 ℃ |

| Stamping pressure range: | ≤300kgf |

| Air consumption: | ≤80 Litre/min |

| Power: | 110V/220V, 50/60HZ, 2KW |

| Dimension: | 1300*900*1900mm |

| Weight: | 250kg |

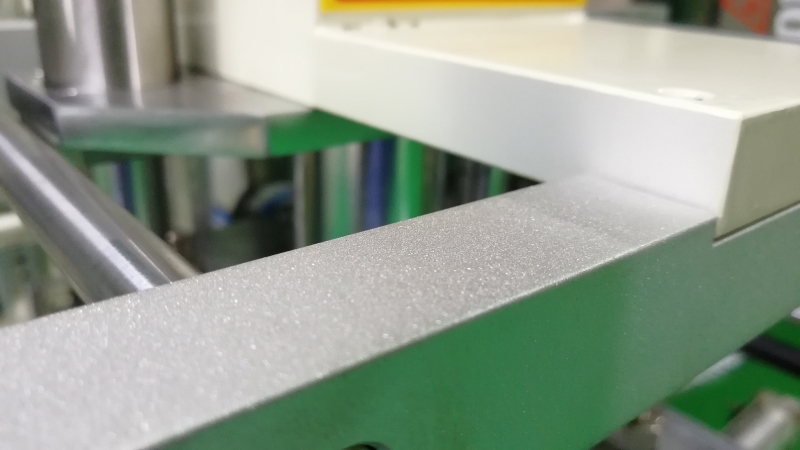

Details:

Samples: