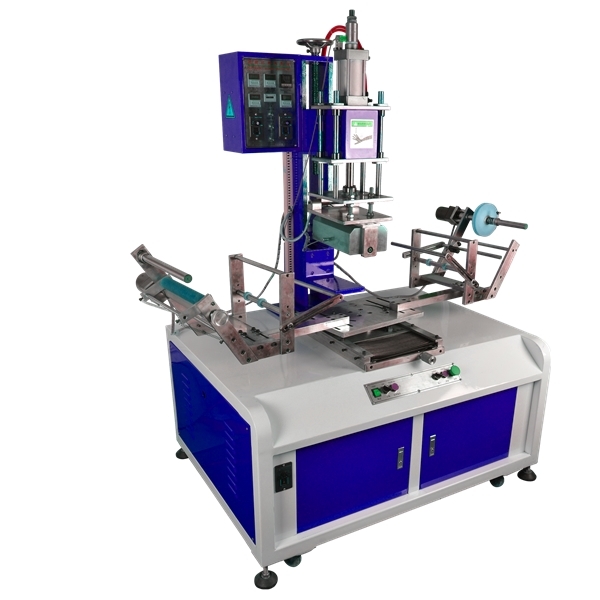

Application:

Exclusively used in heat transfer printing for conical cup, conical bucket, sand bucket and other conical products.

Feature:

1. Equipped with PLC programmable controller text in computer, can be displayed on operation screen. With digital setting, it has high sensitivity. With key-type panel, it is simple and convenient;

2. With gearbox motor driving heat transfer, clearance is small and fan-shape swing stable, Controlled by photoelectronic sensor, the machine has high accuracy;

3. With straight elbow lifting air cylinder, it has fast speed; With oil tank, the machine operates more steady.

4. Workbench can be adjusted back and frond, which is convenient for fast operation;

5. Pressure, temperature and time for transfer printing are adjustable;

6. Positioning transfer printing film with electric eye can load and wind paper automatically and is adjustable;

7. Driven by motor, machine is more suitable to transfer printing for precision product;

8. Height of hot stamping head is adjustable; Heating tube is featured by wrap-around heat conduction, so that hot stamping heat keeps uniform temperature;

Specification:

| Stamping diameter for round part: | 150mm |

| Conicity: | ≤ 5 degree |

| Maximum height of part: | 200mm |

| Stamping speed: | 600 pieces per hour |

| Stamping temperature range: | 300 ℃ |

| Stamping pressure range: | ≤300kgf |

| Air consumption: | ≤80 Litre/min |

| Power: | 110V/220V, 50/60HZ, 2KW |

| Dimension: | 1400*1800*1800mm |

| Weight: | 300kg |

Details:

Samples: