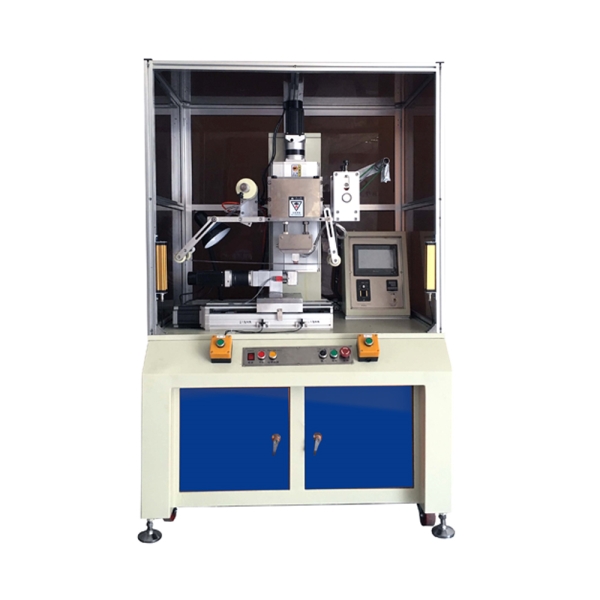

Applications:

This machine is widely used for hot stamping or heat transfer on conical and round part, also square parts. The material can be glass, plastic, ceramic, metal.

Features:

1. The whole machine adopts steel structure body, the column strengthens the welding ribs, and the equipment is more durable;

2. The whole machine car-grade paint high temperature baking, the appearance of high-grade and generous, environmentally friendly non-toxic, lasting does not fade;

3. The machine 304 stainless steel screws, Japan NSK bearing links, to ensure that the machine is strong and durable;

4. High-hardness aluminum, through the large-scale CNC computer precision processing, the machine is high-grade and generous;

5. CNC PLC control, can intelligently store multiple sets of product parameters, call at any time. The touch screen displays the human-machine interface design and is easy to understand;

6. Independent constant temperature control, integrated heating tube control temperature;

7. Using high-precision servo motor positioning fixture, and drive the fixture movement, high precision, smoother;

8. High-precision CNC motor control, the movement of the film is more stable;

9. Hot stamping temperature, pressure, speed adjustable, hot stamping delay, roll paper delay adjustable to meet different printing requirements;

10. The height of the ironing head is adjustable, the printing precision is high;

11. The high-precision magnetic powder structure is used to control the tension of the film, and the tension of the film is detected to ensure the tension of the film and the stability of the movement;

12. The whole machine Taiwan TAIBANG motor / gearbox / governor control, the operation is more stable;

13. The original ATP switch button to ensure the service life and sensitivity.

14. Safety gratings are installed on both sides of the work area to protect the safety of workers.

15. The original imported Taiwan FOTEK sensor switch, precise positioning pattern.

16. External foot switch, with manual/automatic/foot pedal operation options to improve the efficiency of use.

17. Two-hand switch settings to protect the safety of workers.

18. The equipment has automatic detection functions such as rubber roller stop alarm and door open alarm.

19. Protective cover seal design, beautiful appearance and high-grade, operational safety, effectively reduce the impact of dust spots in the production process.

20 . The shuttle can be driven by cylinder or servo motor.

Specification:

| Stamping diameter for round part: | 200mm |

| Printing area: | ¢200*300mm |

| Stamping speed: | 600 pieces per hour |

| Stamping temperature range: | 250 ℃ |

| Stamping pressure range: | ≤300kgf |

| Air consumption: | ≤80 Litre/min |

| Power: | 110V/220V, 50/60HZ, 2KW |

| Dimension: | 1200*850*1900mm |

| Weight: | 300kg |